Bio-Based Nylon-6: The Sustainable Frontier in the Expanding Nylon-6 Market, Research by FMI

Bio-based Nylon-6 is an emerging sustainable alternative, reducing carbon footprint while maintaining performance, reshaping the Nylon-6 market’s future.

NEWARK, DE, UNITED STATES, May 19, 2025 /EINPresswire.com/ -- The nylon-6, a synthetic polymer known for its excellent mechanical strength, abrasion resistance, and versatility, has long been a cornerstone material in industries ranging from textiles and automotive to packaging and electronics. Traditionally derived from petrochemical feedstocks through the polymerization of caprolactam, Nylon-6 dominates the global polymer market due to its durability and adaptability. However, as environmental concerns intensify and sustainability becomes a corporate and consumer priority, an uncommon but rapidly emerging segment of the Nylon-6 market is gaining traction: bio-based Nylon-6. This innovative variation not only redefines material sourcing but also presents a pathway toward a greener polymer industry.

𝐔𝐧𝐝𝐞𝐫𝐬𝐭𝐚𝐧𝐝𝐢𝐧𝐠 𝐍𝐲𝐥𝐨𝐧-𝟔 𝐚𝐧𝐝 𝐭𝐡𝐞 𝐓𝐫𝐚𝐝𝐢𝐭𝐢𝐨𝐧𝐚𝐥 𝐌𝐚𝐫𝐤𝐞𝐭 𝐋𝐚𝐧𝐝𝐬𝐜𝐚𝐩𝐞

The Nylon-6 market has historically been shaped by its applications in textiles, industrial yarns, automotive components, and packaging films. With a global market valued at several billion dollars and expected to grow steadily due to increasing demand in end-use sectors, the polymer’s traditional production relies heavily on fossil fuel-derived caprolactam. This process, while well-established, involves significant carbon emissions and resource depletion, which have recently come under scrutiny as governments worldwide tighten environmental regulations.

𝐌𝐚𝐤𝐞 𝐈𝐧𝐟𝐨𝐫𝐦𝐞𝐝 𝐃𝐞𝐜𝐢𝐬𝐢𝐨𝐧𝐬 – 𝐀𝐜𝐜𝐞𝐬𝐬 𝐘𝐨𝐮𝐫 𝐒𝐚𝐦𝐩𝐥𝐞 𝐑𝐞𝐩𝐨𝐫𝐭 𝐈𝐧𝐬𝐭𝐚𝐧𝐭𝐥𝐲! https://www.futuremarketinsights.com/reports/sample/rep-gb-1291

Despite consistent growth, the conventional Nylon-6 market faces growing challenges linked to sustainability goals, pushing manufacturers and researchers alike to explore alternatives. Among these alternatives, bio-based Nylon-6—also called renewable Nylon-6 or bio-nylon—has emerged as a compelling candidate. By leveraging biomass as a raw material source, bio-based Nylon-6 promises to reduce the polymer’s environmental footprint significantly.

𝐁𝐢𝐨-𝐁𝐚𝐬𝐞𝐝 𝐍𝐲𝐥𝐨𝐧-𝟔: 𝐏𝐫𝐨𝐝𝐮𝐜𝐭𝐢𝐨𝐧 𝐚𝐧𝐝 𝐃𝐢𝐬𝐭𝐢𝐧𝐠𝐮𝐢𝐬𝐡𝐢𝐧𝐠 𝐅𝐞𝐚𝐭𝐮𝐫𝐞𝐬

Bio-based Nylon-6 is produced by converting renewable feedstocks such as glucose derived from corn or sugarcane into caprolactam, the monomer necessary for polymerization. Unlike traditional caprolactam production, which depends on benzene extracted from crude oil, bio-nylon synthesis incorporates green chemistry principles and biotechnological advancements. For example, chemical companies have developed proprietary catalytic and fermentation processes that transform plant-based sugars into bio-based caprolactam with competitive yield and purity.

This production route results in Nylon-6 with chemical and physical properties nearly identical to its petrochemical counterpart, ensuring compatibility with existing manufacturing equipment and product specifications. Importantly, the use of renewable raw materials means that bio-based Nylon-6 carries a significantly lower carbon footprint, often boasting reductions of up to 60-70% in greenhouse gas emissions compared to conventional Nylon-6. This distinction underpins the growing interest in bio-nylon as industries strive to meet ambitious sustainability targets.

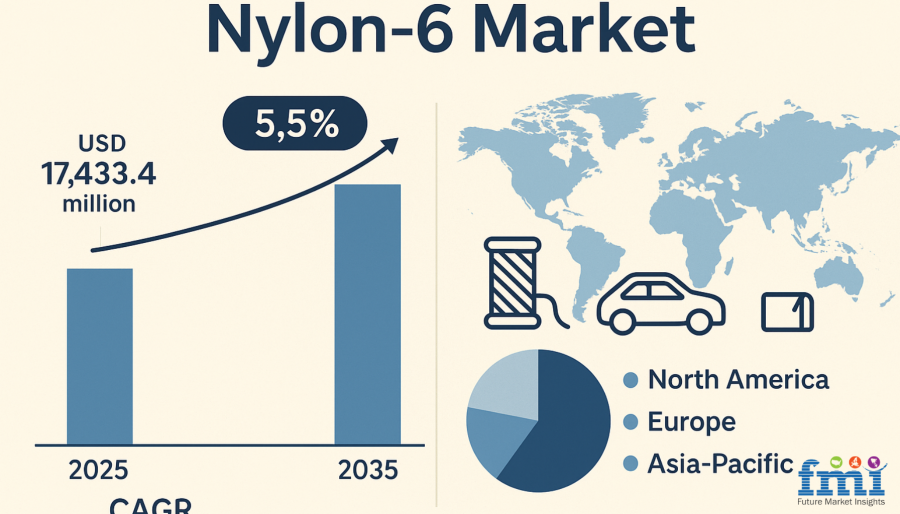

The forecast indicates that the Nylon-6 market will grow from its initial value of USD 17,433.4 million in 2025 to USD 29,778.9 million in 2035 with a predicted 5.5% Compound Annual Growth Rate (CAGR).

𝐌𝐚𝐫𝐤𝐞𝐭 𝐃𝐫𝐢𝐯𝐞𝐫𝐬: 𝐄𝐧𝐯𝐢𝐫𝐨𝐧𝐦𝐞𝐧𝐭𝐚𝐥 𝐏𝐨𝐥𝐢𝐜𝐢𝐞𝐬 𝐚𝐧𝐝 𝐂𝐨𝐧𝐬𝐮𝐦𝐞𝐫 𝐃𝐞𝐦𝐚𝐧𝐝

The increasing adoption of bio-based Nylon-6 is fueled by a convergence of regulatory, corporate, and consumer pressures. Governments across North America, Europe, and Asia have enacted stricter mandates on plastic production, waste management, and carbon emissions, incentivizing manufacturers to transition toward renewable materials. For example, the European Union’s Circular Economy Action Plan and the U.S. Environmental Protection Agency’s sustainability guidelines encourage investment in bio-based polymers as a key strategy to reduce environmental impact.

𝐔𝐧𝐥𝐨𝐜𝐤 𝐂𝐨𝐦𝐩𝐫𝐞𝐡𝐞𝐧𝐬𝐢𝐯𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 – 𝐄𝐱𝐩𝐥𝐨𝐫𝐞 𝐭𝐡𝐞 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭 𝐍𝐨𝐰: https://www.futuremarketinsights.com/reports/polyamide-6-market

Consumer awareness is another critical factor driving demand. In markets such as apparel and automotive, eco-conscious customers are increasingly scrutinizing the environmental credentials of the products they buy. This shift is prompting brands to incorporate bio-nylon fibers in sustainable fashion lines or automotive components that emphasize lower embedded carbon. Prominent companies, including global chemical producers and fiber manufacturers, have announced pilot projects and commercial launches of bio-based Nylon-6, signaling growing confidence in its market potential.

𝐀𝐩𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐚𝐧𝐝 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐈𝐦𝐩𝐥𝐢𝐜𝐚𝐭𝐢𝐨𝐧𝐬 𝐁𝐞𝐲𝐨𝐧𝐝 𝐂𝐨𝐧𝐯𝐞𝐧𝐭𝐢𝐨𝐧𝐚𝐥 𝐔𝐬𝐞𝐬

While traditional Nylon-6 applications are well documented, bio-based Nylon-6 is carving out unique niches that go beyond mere substitution. In the textile industry, bio-nylon fibers are used to create garments that combine performance with eco-friendliness, appealing to premium and environmentally aware consumers. In the automotive sector, bio-nylon parts help manufacturers achieve lighter and greener vehicles, aligning with regulations on emissions and fuel efficiency.

Moreover, bio-based Nylon-6 is gaining traction in packaging applications, where biodegradable or compostable polymer blends are increasingly demanded to tackle plastic pollution. Bio-nylon’s inherent recyclability and lower environmental impact position it as a material of choice for future sustainable packaging solutions. These emerging uses demonstrate how bio-based Nylon-6 is not just a greener alternative but an enabler of innovative product design and circular economy principles.

𝐂𝐡𝐚𝐥𝐥𝐞𝐧𝐠𝐞𝐬 𝐚𝐧𝐝 𝐭𝐡𝐞 𝐑𝐨𝐚𝐝 𝐀𝐡𝐞𝐚𝐝

Despite its promise, the bio-based Nylon-6 market is not without hurdles. Higher production costs relative to conventional Nylon-6 remain a barrier to widespread adoption, driven by feedstock variability and less mature manufacturing technologies. Supply chain constraints also limit the scalability of bio-nylon production, as biomass availability and processing infrastructure are still developing in many regions.

Performance concerns, although largely addressed through ongoing research, occasionally arise regarding the mechanical properties and durability of bio-based Nylon-6 compared to traditional polymers, necessitating further refinement. Nonetheless, industry experts predict that ongoing advances in biotechnology, process optimization, and economies of scale will gradually reduce these limitations.

𝐏𝐨𝐥𝐲𝐦𝐞𝐫𝐬 & 𝐏𝐥𝐚𝐬𝐭𝐢𝐜𝐬 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬: https://www.futuremarketinsights.com/industry-analysis/polymers-and-plastics

Looking ahead, the sustainable Nylon-6 market is expected to grow robustly, driven by increasing regulatory support and escalating consumer demand for greener materials. By 2030, bio-based Nylon-6 could capture a significant share of the global Nylon-6 market, transforming the polymer industry and setting new standards for sustainable manufacturing.

𝐊𝐞𝐲 𝐒𝐞𝐠𝐦𝐞𝐧𝐭𝐬 𝐏𝐫𝐨𝐟𝐢𝐥𝐞𝐝 𝐢𝐧 𝐭𝐡𝐞 𝐆𝐥𝐨𝐛𝐚𝐥 𝐍𝐲𝐥𝐨𝐧-𝟔 𝐌𝐚𝐫𝐤𝐞𝐭

By Type:

- Nylon-6 (PA6) Fiber

- Nylon-6 (PA6) Resin

By Application:

- Transportation

- Electrical and Electronics

- Textiles

- Industrial Application

- Other (include music, healthcare, coating sector)

By Region:

- North America

- Latin America

- Europe

- Asia Pacific

- Middle East & Africa

𝐑𝐞𝐥𝐚𝐭𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬:

Forestry Lubricants Market Share Analysis: https://www.futuremarketinsights.com/reports/forestry-lubricants-market-share-analysis

Polyurethane Dispersions Market Share Analysis: https://www.futuremarketinsights.com/reports/polyurethane-dispersions-market-share-analysis

Wood-based Fiber Market Share Analysis: https://www.futuremarketinsights.com/reports/wood-based-fiber-market-share-analysis

Electronic Thermal Materials Market Share Analysis: https://www.futuremarketinsights.com/reports/electronic-thermal-materials-market-share-analysis

Protective Textiles Market Share Analysis: https://www.futuremarketinsights.com/reports/protective-textiles-market-share-analysis

𝐀𝐛𝐨𝐮𝐭 𝐅𝐮𝐭𝐮𝐫𝐞 𝐌𝐚𝐫𝐤𝐞𝐭 𝐈𝐧𝐬𝐢𝐠𝐡𝐭𝐬 (𝐅𝐌𝐈)

Future Market Insights, Inc. (ESOMAR certified, recipient of the Stevie Award, and a member of the Greater New York Chamber of Commerce) offers profound insights into the driving factors that are boosting demand in the market. FMI stands as the leading global provider of market intelligence, advisory services, consulting, and events for the Packaging, Food and Beverage, Consumer Technology, Healthcare, Industrial, and Chemicals markets. With a vast team of over 400 analysts worldwide, FMI provides global, regional, and local expertise on diverse domains and industry trends across more than 110 countries.

Join us as we commemorate 10 years of delivering trusted market insights. Reflecting on a decade of achievements, we continue to lead with integrity, innovation, and expertise.

𝐂𝐨𝐧𝐭𝐚𝐜𝐭 𝐔𝐬:

Future Market Insights Inc.

Christiana Corporate, 200 Continental Drive,

Suite 401, Newark, Delaware - 19713, USA

T: +1-347-918-3531

For Sales Enquiries: sales@futuremarketinsights.com

Website: https://www.futuremarketinsights.com

LinkedIn| Twitter| Blogs | YouTube

Ankush Nikam

Future Market Insights Global & Consulting Pvt. Ltd.

+ +91 90966 84197

email us here

Visit us on social media:

Other

Distribution channels: Chemical Industry

Legal Disclaimer:

EIN Presswire provides this news content "as is" without warranty of any kind. We do not accept any responsibility or liability for the accuracy, content, images, videos, licenses, completeness, legality, or reliability of the information contained in this article. If you have any complaints or copyright issues related to this article, kindly contact the author above.

Submit your press release